The airend in your

compressor package wants very little from its owner. It needs air to compress,

some place to put it, and most important, an adequate supply of clean,

relatively cool oil to seal, lubricate and remove heat. Your airend doesn’t

directly care if the oil sump is topped off or if the cooler had a 12-degree

approach to ambient the day you bought it.

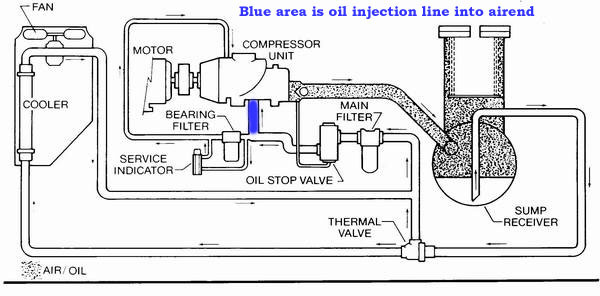

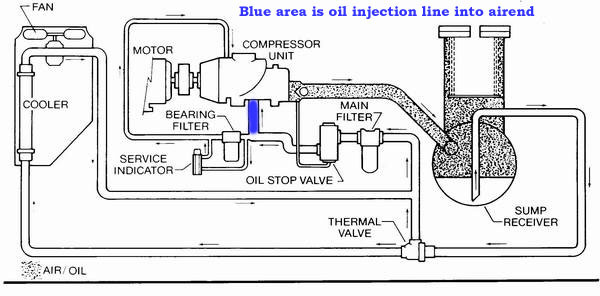

What matters most immediately is the temperature and

pressure of the oil at

the point where it is injected into the airend,

downstream of the cooler, thermal valve pipework and filters today.

Perhaps the most frequent question we ask of

technicians attempting to solve airend related problems such as overheating, low

air delivery or noise is, “What’s the oil injection pressure?” Normally,

on airends with no oil pump, this would track about 30 psig below sump pressure

at full load, however not all brands are the same. Airend manufacturers use

different size injection ports and points of injection to find the most

efficient combination.

If there were a proper amount of oil supplied to the airend you would normally see a 30 to 40 degree temperature rise from oil injection temperature to airend discharge temps. Low oil injection pressure will cause that differential to increase considerably. If the pressure is low, find out why, chasing the pressure drops back through the oil filter housing, cooler, pipework, thermal valve and sump. Yes, we have seen blockages at the oil outlets of the sump.