Is Summer Heat Killing Your Air Compressor?

While employed as service manager for an American compressor manufacturer many years ago, I received an urgent phone call from a service technician in the Middle East. His foreman had told him to check the temperatures on their two new air cooled, single stage, reciprocating compressors. Not having a temp gun or even a thermometer, he grabbed the first pump’s copper discharge line and received a very nasty burn to his hand. To verify the problem was only in one machine, he then grabbed a second one and burned the other hand.

It was my job to tell him that the normal air discharge temperature of his compressor in the desert sun could approach 500 degrees F. Now … add this warning to the service manual: “Do not touch discharge pipe. It may cause physical injury!”

Why do I bring this up? The heat of summer is upon us! Are you and your air compressor ready for the rising temperatures? Here are some points to consider.

Your air compressor generates a tremendous amount of heat. When ambient air is compressed to do work for you, considerable heat of compression is released. As a rough illustration, the heat of compression released from a 100 horsepower air compressor could heat 4 homes in the worst of winter. If not handled properly in the summer, that heat can become an enemy to your air system.

Most compressors sold today have little tolerance for extreme temperatures. In this competitive world, unless oversized coolers are ordered as an option, there will be very little excess capacity available in what comes in your packaged rotary screw compressor. It is most important to assure that the coolers are kept clean inside and out. Oil flooded rotary screw compressors typically operate in the 160 – 180 degree F range. That same machine will probably not shut down due to high temperature until it reaches 230 degrees F. But bad things begin to happen long before it shuts down.

1. Excessive heat kills most compressor oils. It is a well accepted rule of thumb that you cut oil life expectancy by half for every 20 degree rise above normal operating temperature. In many cases, the high price you pay for synthetic compressor oils is squandered because the oil breaks down prematurely due to overheating. To protect from high acid numbers, loss of lubricity and increased viscosity, long oil change intervals must be monitored with frequent lube analysis, particularly when exposed to high ambient temperatures.

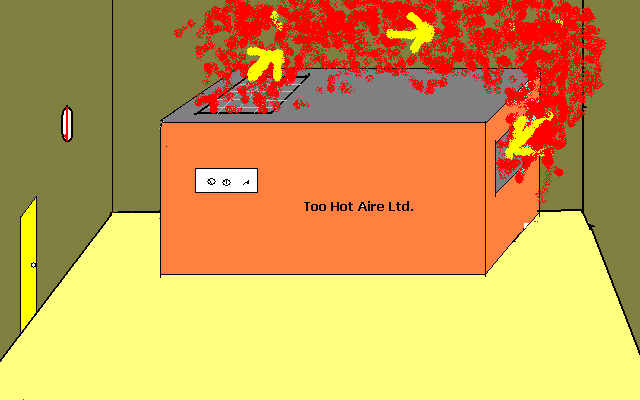

The fellow who owns the compressor shown below also paid for synthetic lubricant.

2. Air compressors operating in elevated temperatures pass a lot more water into your air system. An air cooled rotary screw compressor in a hot, poorly ventilated, dusty environment can pass six times the water through your air system as a clean machine running at normal temperatures. Remember… for every 20 degree F rise in discharge air temperature, compressed air will carry twice as much water vapor to condense out in your air piping and equipment

3. An air compressor running at elevated temperatures is not an efficient compressor. Hot compressed air will experience pressure losses as it passes through air treatment and distribution pipework.

4. When your airend is running at elevated temperatures it is slowly opening up its clearances and accelerating wear. This will lead to less efficient operation and shortened life down the road.

Q. What are a few things I should check if my compressor is running hot?

A. What is the ambient temperature? Most lubricated, air cooled, rotary screw compressors run 100 to 110 degrees F above the ambient temperature. If your compressor room is over 100 degrees, you are already in trouble. Cross flow ventilation is advisable in non ducted compressors. If your compressor oil sump or airend discharge is more than 120 degress F over ambient temperature in the room, you need to find out why.

1. Is the compressor full of coolant/lubricant? The compressor oil serves as coolant in oil flooded rotary compressors. In most modern rotary screws, the compressor oil is circulated 7 or more times per minute through the machine. You can see why the oil level becomes more critical in the summer.

2. Is hot air blowing from the entire cooler? A blocked radiator type cooler will drive oil and compressed air temperatures up and it is, by far, the single most common cause of overheating in air cooled rotary screw compressors. Although this little task is a real money maker for compressor service companies, blowing out the external fins of the oil cooler and aftercooler with compressed air could easily be done by most plant maintenance personnel.

3. Is your inlet air filter plugged? The heat released by air compression is related to the compression ratios achieved. If your inlet filter is plugged, you might be as low as 10 psig at the compressor inlet valve. In order to discharge air at 100 psig, it must be compressed 10 times, rather than 7 at the normal atmospheric, sea level inlet air pressure of 14.7 psi. This would generate more heat and use more energy.

Let that poor compressor breathe. Have you ever seen a compressor room that looks like this? Hot air blowing out of the compressor’s cooler has no quick escape from the room so much of it is sucked back in the inlet end of the machine.

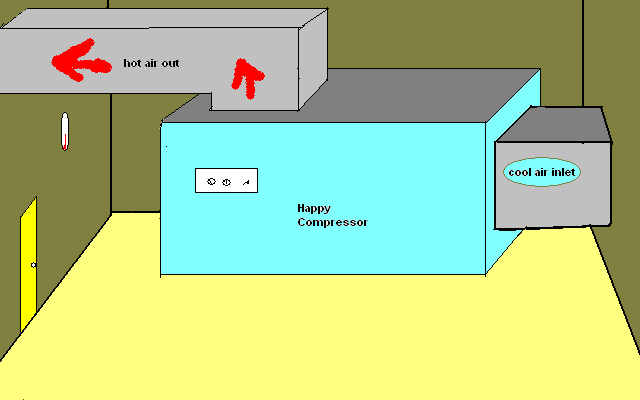

Compressors installed in a small room benefit from ducting the hot air out of the room. The ductwork cross section should be at least as large as the cooler. It does not need to be anything fancy or factory made. Whether it’s made from sheet metal, self tapping screws and duct tape or plywood with hinged doors, anything that ducts the heat out of the room will do. Remember to leave a door to reach and clean the coolers.

Unenclosed compressors need ventilation too. Cross flow is always best with an exhaust fan and louvered hot air discharge near the top of the room. Remember to size the vent at least as large as the cooler, and the vent fan should displace more cfm than the compressor’s cooling fan. Cooling fan cfm ratings can be found in the specifications for most air cooled rotary screw compressors.

Paying close attention to the operating temperatures of your rotary screw compressors and protecting them from the summer’s heat will extend the life of your air compressors and your oil.